PCM2 34 and 48 Channel Power Distribution Modules - the smart solution to race car wiring by OBR

The intelligent control and distribution of battery power in a modern racing car. The PCM2 and PCM2 Lite are innovative, intelligent and programmable solid state modules which replaces relays and circuit breakers, simplifies wiring harnesses and provides diagnostic capabilities.

Variations

| P/N# | Model | Description | Price in USD |

|---|---|---|---|

| OB967 | PCM2 LITE | Fully programmable 34 channel solid state power control module | 2050 |

| EMC-009 | PCM2 LITE | Connector kit | 49 |

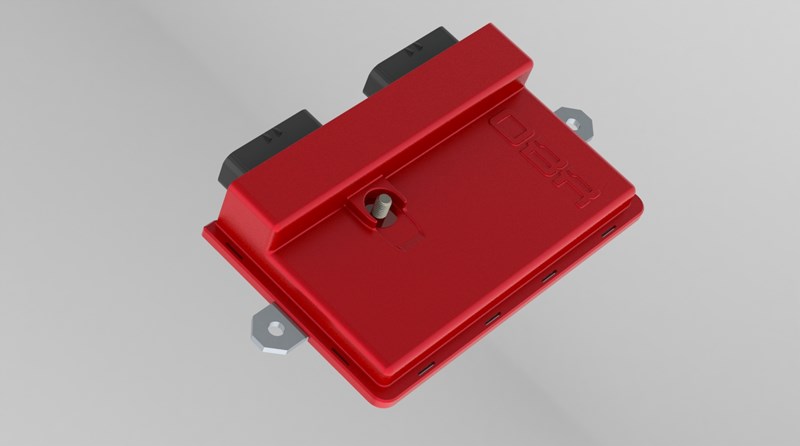

PCM2 Lite Power Distribution Module with 34 channels

Inputs

- 1 x M8 stud for battery power input.

- 8 x analog 0-5V inputs with 47 kOhm pull-up resistors.

- 8 x digital inputs triggering on low / open / high signal levels.

- 2 x CAN ports.

- 1 x reset switch, resetting only eventual channels in fault mode.

Outputs

- 22 x high side power outputs (typical up to 17A continuous), max 300 Hz PWM, max current 30A.

- 8 x high side high power outputs (typical up to 25A continuous), max 300 Hz PWM, max current 60A.

- 2 x high side wiper motor outputs (typical up to 17A continuous), max 300 Hz PWM, max current 30A.

- 2 x half bridge high power PWM outputs (typical up to 25A continuous). Outputs can be configured as low side, high side and as full H-bridge, max 25 kHz PWM, max current 40A.

- In-rush current capability 150A.

- Maximum recommended continuous current draw 140A.

Multiple outputs can be grouped for extreme high current applications.

Please note that the maximum recommended current draw per channel is limited by the

connector contacts - not by PCM2’s driver stages. We have rated the individual channel’s

current draw in relation to the connector manufacturer’s specifications.

Communication

- 2 CAN ports with up to 64 user defined input and up to 64 user defined export channels.

- Baud rates from 10 kbps up to 1 Mbps.

- CAN routing between ports.

- Software selectable termination of each CAN port.

- RS232 diagnostic port.

Dimensions

- Dimensions (very small and light)

- Weight 750g (26 oz.)

- 236 x 118 x 39mm (9 1/4" x 4 5/8" x 1 1/2")

- Aluminum heat sink and plastic cover

- 2 automotive connectors with gold plated terminals

Infobox

About Power Distribution

In the past, a production car uses relays and fuses or circuit breakers to protect the electrical system from short circuit damage and even fire in case of a fault in the wiring.

Such a system is not suitable for use in a competition car. Relays and fuses are exposed to a harsh environment of heat and vibration which can cause unintended electrical shut downs. Furthermore, the wiring for fuses and relays are often very complex and this makes fault tracing complicated, in particular if errors happen during competition.

In the modern world of electronics we have for many years done away with these vulnerable components and have replaced them with computer controlled modules. Instead we have a microprocessor that monitors switch requests, current draws and load conditions. OBR systems do not just shut down if there is a fault, they evaluate and analyze the cause of the failure and then reset failed channels automatically and test the outputs.

OBR's award winning PCM2, the new PCM LITE and the compact PCM AC power control modules (sometimes referred to as PDU or PDM) take the whole Power Control Module concept much further than conventional modules. Based on our experience and success with developing power boxes, OBR PCM's are very powerful, flexible and technically advanced modules. OBR PCM2, PCM LITE and PCM AC are huge steps ahead of our competitors, in technology, features and their very high current handling ability.

Our PCM modules provide an effective and inspired alternative to conventional relays, circuit breakers, fuses and wires that can so often be a tangle of complexity and untidiness around a typical racing car’s power junction box.

Furthermore, they monitor status, temperature and current draw for each individual output, an effective tool in detecting and preventing faults.

OBR PCM's have all been designed to handle very high inrush currents as well as high continuous current handling. The inrush current is drawn in the instant when, for example, a fan is switched on or the paddle shift air compressor starts. Our PCM's are capable of handling this kind of current draw of up to 300A over a short period of time.

With PCM2, PCM LITE and PCM AC OBR provide the user with modules which can handle virtually limitless event based configuration options. By having the control logic arranged around user defined events it is the intention to offer an almost unrestricted control strategy to the end user.

OBR supply PCM LITE with a pre-configured setup ensuring a simple and straight forward installation – but still offering the user full access to write the control logic.

When evaluating power control modules it is very important to judge the weight of a module correctly. To handle high currents and to dissipate the heat associated with these high currents, the module should feature the highest content of copper feasible within the design rules.

When it comes to selecting a PCM powerbox, remember the lightest unit is very likely not the most reliable!