Pro motorsport, Hotrod, power boats

OBR Control Systems Inc is a world wide supplier of automotive electronics. We specialize in OEM engine controllers for prototype engine development and engine testing as well as for motorsports. Engine systems can be supplied for engines having up to 16 cylinders with direct injection, port injection or a combination of the two. Systems can be supplied for gasoline as well as for diesel engines. OBR products are used in the most demanding environments ensuring performance and reliability.

Variations

| P/N# | Model | Description | Crank and Cam Triggers | Price in USD |

|---|---|---|---|---|

| EFF14B-000 | Engines with max 8 cylinders | Price is Ex Works and for delivery in North America only | VR crank and cam sensor inputs | 1080 |

| EFF14B-100 | Engines with max 8 cylinders | Price is Ex Works and for delivery in North America only | Hall effect crank and cam sensor inputs | 1080 |

| EFF14B-400 | Engines with max 8 cylinders | Price is Ex Works and for delivery in North America only | VR crank and Hall effect cam sensor inputs | 1080 |

Euro-4 Advanced System for Engines with up to 8 Cylinders - a Perfect choice for LS3 / LS7 Engines

System overview

- PowerPC microprocessor

- 8 cylinder fully sequential fuel injection

- Dual-stage fuel injection for stand off injectors

- Ignition output handles both logic and inductive coils.

- Drive by wire throttle PID control

- On-board data logger with high speed sampling rates (200hz)

- Automatic fuel mapping

- Closed-loop lambda control

- Closed-loop boost control

- Closed-loop traction control

- Closed-loop paddle shift control

- Closed-loop variable camshaft control (VCT, VVT, VANOS etc.)

- Closed-loop direct injection fuel pump Bosch and Hitachi (external driver required)

- Closed-loop water pump control

- Closed-loop pit lane speed control

- Closed-loop idle control (ETB, stepper motor, ISC valve and ignition)

- 2 driver selectable calibrations

Inputs

- 20 analog inputs (0-5v)

- 8 user defined CAN inputs

- 4 trigger inputs (Hall/VR) for crank and cam sensors

- 4 wheel speed inputs (Hall)

- 3 spare digital inputs

- 2 knock sensors

- Built-in wide band lambda controller plus inputs for 3 external lambda controllers

- Built-in barometric pressure sensor

Outputs

- 8 fuel injector drivers

- 4 inductive and 4 logic ignition drivers

- 8 multipurpose PWM and relay outputs

- 1 wide band lambda sensor heater

- 1 electronic throttle body (full H-bridge)

- 1 stepper motor driver (full 4-phase)

- 4 independent 5V sensor power supply

Communications

- 2 CAN 2.0B interfaces

- Multiple pre-programmed and user defined CAN export and import

- FIA RX datalogger

- Bosch ABS data import

- General data import and export

- VW Dash protocol (500Kbit)

- 16 CAN identifiers available for export

- 2 CAN identifiers available for import

Special features

- 4 lambda sensors for individual closed loop PID cylinder trim

- Special engine trigger patterns including several for motorcycle engines

- Control strategy for paddle shift and air compressor

- Control strategy for sequential closed loop gear change

- Traction control with target slip maps and PID control

- Pit lane, launch and external adjustable manual limiter

- Programmable firing order

- Knock control

- Comprehensive CAN features

- Special version available with fully encrypted software

- Launch control (with advanced rpm vs time curve)

General

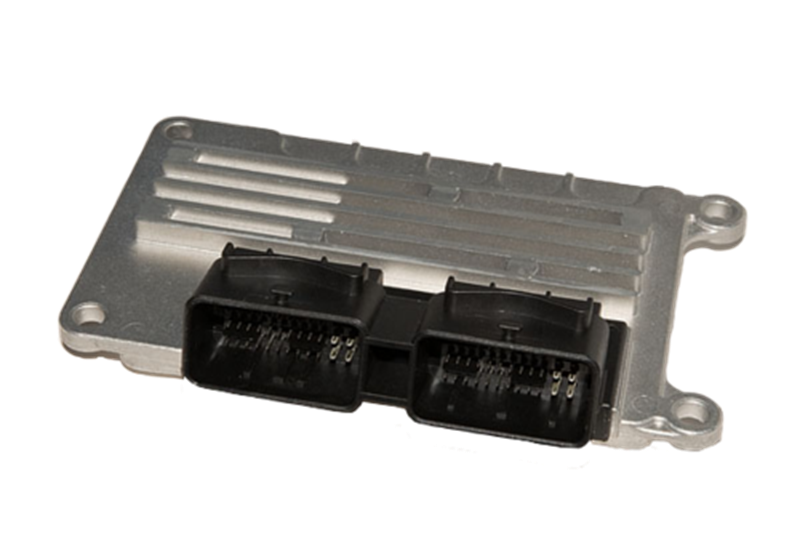

- Dimensions (very small and light)

- Weight 365g (13 oz.)

- 165 x 95 x 21mm (6 1/2" x 4 3/4" x 7/8")

- All aluminum and high-end vibration stable SMD PCB

- 2 automotive Molex connectors with high pin density (96 in total)

Conditions for usage

- Temperature range -40 to 125 Celsius (-40 to 257 Fahrenheit)

- Power supply 7-16v

- Splash-proof

Emissions

These parts are legal for sale and use on uncontrolled (Non-Emissions Controlled) vehicles and on off-road racing vehicles ONLY.

WARNING: It is against the law to install these parts on an emissions controlled vehicle

All OBR products are exclusively manufactured for racing purposes. Installing these products on any vehicle eliminates the legal use, in any capacity, on public roads/highways and may be subject to fines and/or criminal liability as per the Clean Air Act.

Product information

| Description | Downloads |

|---|---|

|

OBR Euro-4 product information |

|

Pinout

| Description | Downloads |

|---|---|

|

Pinout Euro-4 PDF |

|

Data Files

| Description | Downloads |

|---|---|

|

Euro-4 data file version 346 |

|