OBR Crate Engine Control Packs - 7.3 V8 Godzilla - 5.2 V8 GT500 - 2.3L 4-Cyl TiVCT GTDi - 7.3 V8 Godzilla 2023 - Coyote 5.0/5.2 - GM LS and LT Engines - 01.09.2024.

Easy Installation - Optimized Driveability - Turn Key Control Pack

Variations

| P/N# | Model | Description | Price in USD |

|---|---|---|---|

| OB201 | Kit 1 | Level 1 controller kit for Godzilla crate engine without engine harness | 2100 |

| OB202 | Kit 2 | Control pack level 2 includes ECU with tune for crate engine, engine and power harnesses and TMAP sensor | 3550 |

| OB203 | Kit 3 | Control pack level 3 includes ECU with tune for crate engine with stage 1 camshaft, engine and power harnesses and TMAP sensor | 3550 |

| OB204 | Kit 4 | Level 4 controller kit for supercharged Godzilla crate engine, includes 8 high flow injectors, 3 bar TMAP sensor and updated base calibration; wiring included | 4110 |

| OB205 | Kit 5 | Control pack level 5 includes ECU with tune for crate engine with stage 1 camshaft and BTR intake with 95 mm throttle body, engine and power harnesses and TMAP sensor | 3550 |

| OB206 | Kit 6 | Control pack level 6 includes ECU with tune for crate engine with stage 1 camshaft, Ford Performance intake and 92 mm throttle body, engine and power harnesses and TMAP sensor | 3550 |

| OB207 | Kit 7 | Control pack level 7 includes ECU with tune for crate engine with stage 1 camshaft and the special front cover from Indy Power Products, engine and power harnesses and TMAP sensor | 3550 |

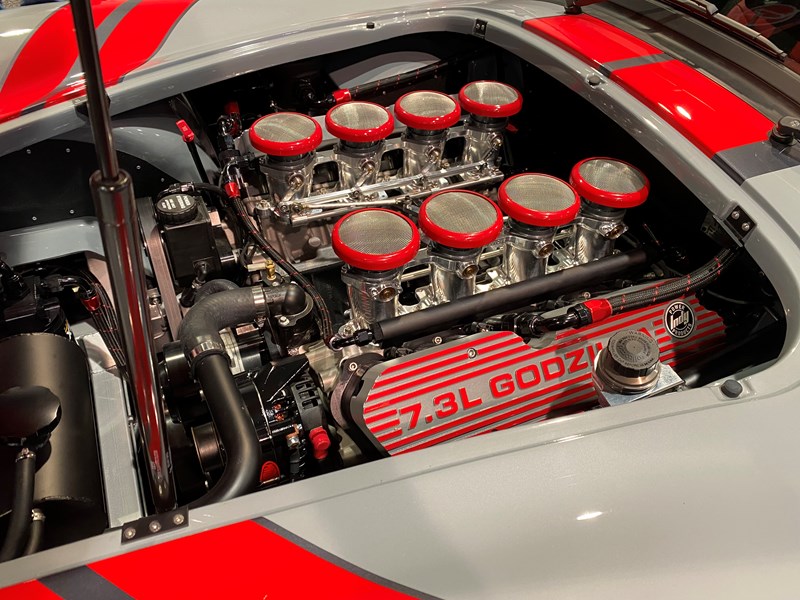

| OB208 | Kit 8 | Control pack level 8 includes ECU with tune for crate engine with stage 1 camshaft and intake with 8 individual stacks by InnoV8, engine and power harnesses and TMAP sensor | 3550 |

| OB209 | Kit 9 | Control pack level 9 is a new kit developed for an engine fitted with the new intake from Godzilla version 2023, the 2023 throttle body, engine and power harnesses plus a TMAP sensor. | 3550 |

| OB251-F | Pedal | Throttle pedal kit with cable | 169 |

| OB301 | Plug | Coolant plug for Godzilla engine | 39 |

| OB510-8 | NGK | NGK Racing spark plug heat range 8, set of 8. Strongly recommended, we use these in our test engines. | 66 |

| OB510-9 | NGK | NGK Racing spark plug heat range 9, set of 8 | 66 |

| OB410 | Ignition | High temperature, high performance plug wires. Set of 8. Strongly recommended, we use these in our test engines. | 235 |

| OB420 | Ignition | Plug wire heat insulation socks. Set of 8. | 68 |

| OB360-23 | Performance | Performance kit with 2023 intake plus 86 mm ETB. Typically +10 lb.ft and +10 hp on standard engine. | 525 |

| OB302 | Alternator | Alternator installation kit, complete | 985 |

| OB255 | Sensor | Fuel pressure sensor with cable, 150 psi | 145 |

| OB260 | Sensor | Oil pressure sensor, adapter and cable for OBD II display | 164 |

| OB6312-V | Sensor | Wide band lambda sensor for closed loop fuel control, each | 248 |

| OB1784 | Sensor | 3 bar absolute TMAP sensor for supercharged and turbocharged engines | 62 |

| OB804 | Injector | Kit with 8 high flow fuel injectors | 520 |

| OBW187 | Wiring | Engine wiring harnesss as included with level 2, 3 and 4 kits | 1650 |

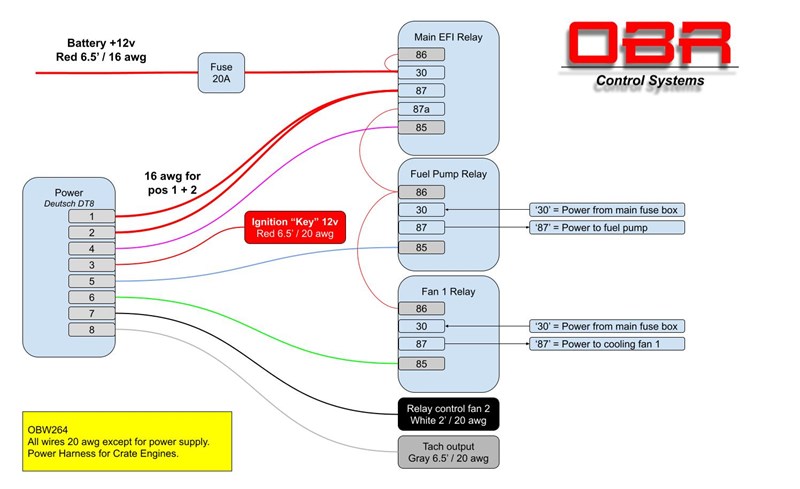

| OBW264 | Wiring | Power harness with 3 relays and 30A fuses | 165 |

| OBW281 | Connector | Plug with pull-up resistor for tach configuration | 9 |

| OBW255 | OBD II | OBD II adapter cable for kits up to 09.30.2022 | 70 |

| OB256 | Comms | Optional ECU communication & tune kit with connection cables | 544 |

Ford 7.3 V8 'Godzilla' up to 2022 Crate Engine Control Packs - updated 01.10.2024

What the base kits includes....

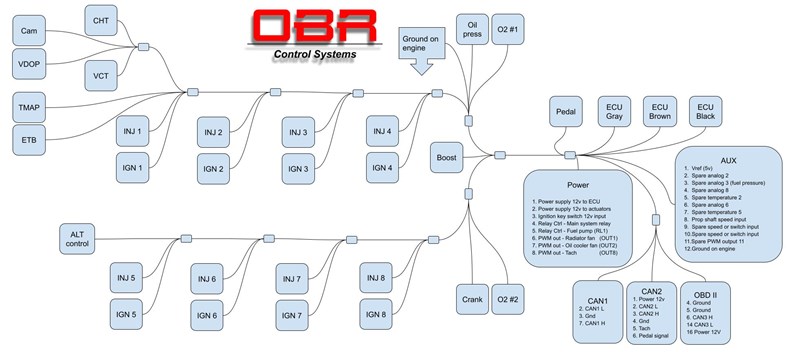

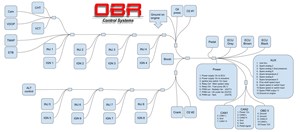

Our kits for the 7.3 V8 'Godzilla' engine are based on our E8G ECU. This controller is specially configured to control standard features on the Ford engine, you do NOT have to change or modify any sensor or actuator on the engine.

All our wiring harnesses are designed and built in our shop in Livonia in Michigan.

Our ECUs are all manufactured in the European Union.

Our level 1 base crate engine kit OB201 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- ECU connector kit with terminals and fitted with 2 communication links and power supply link. With this kit you can build your own engine harness or adapt to the original Ford engine harness.

- E8G gasoline calibration for the standard crate engine using standard fuel injectors, ignition coils, throttle body and sensors. Loads of power and torque.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

Our level 2 crate engine kit OB202 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine using standard fuel injectors, ignition coils, throttle body and sensors. Loads of power and torque.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 3 kit OB203 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine with a stage 1 camshaft and using standard fuel injectors, ignition coils, throttle body and sensors. Significant increase of power and torque over the standard engine.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 4 crate engine kit OB204 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- 8 high flow fuel injectors.

- E8G gasoline base calibration for a standard crate engine intended for use with turbos or a supercharger, high flow fuel injectors, standard ignition coils, throttle body, 3 bar TMAP and sensors.

- Bosch 3 bar TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 5 kit OB205 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine with a stage 1 camshaft, fitted with the BTR low profile intake and using standard fuel injectors, ignition coils, throttle body and sensors. Significant increase of power over the standard engine.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 6 kit OB206 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine with a stage 1 camshaft, fitted with the Ford Performance intake with a 92 mm throttle body and using standard fuel injectors, ignition coils, throttle body and sensors. Significant increase of power and torque over the standard engine.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 7 kit OB207 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine with a stage 1 camshaft, the special front cover from Indy Power Products and using standard fuel injectors, ignition coils, throttle body and sensors. Significant increase of power and torque over the standard engine.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

Our level 8 kit OB208 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable complete relays for main power, fuel pump and coolant fan, all fitted with 30A fuses.

Furthermore, you will also have wires for your tach and an oil coolant fan.

- E8G gasoline calibration for the standard crate engine with a stage 1 camshaft, fitted with the InnoV8 with the individual 8 stacks and using standard fuel injectors, ignition coils, throttle body and sensors. Significant increase of power and torque over the standard engine.

- Bosch TMAP air pressure and air temperature sensor used for calibration.

- OBD II link.

---

These kits all controls standard components:

- Standard drive-by-wire throttle body, reading its SENT data stream directly.

- Variable camshaft timing in closed loop.

- Variable oil pressure control in closed loop.

- Standard ignition coils.

- Alternator charging.

More about our engine and power wiring harnesses

Our harnesses are built here in Livonia and uses aircraft type wire with an insulation of cross-linked, modified ethylene tetrafluoreothylene co-polymer (ETFE). The insulation resists high PH cleaning fluids, fuels, lubricating oils, and many other chemicals.

The wires can withstand extreme test temperatures, ranging from cold bend at -85°F through to 390°F. These wires are a mechanically tough, flame retardant and weight saving solution to many motorsport and aerospace applications.

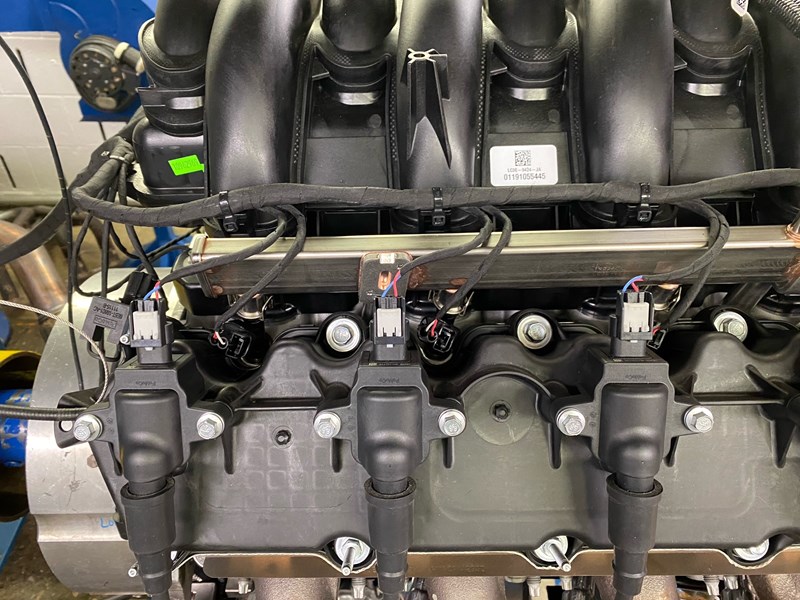

The engine harness is fitted with new OEM connectors and terminals for sensors, injectors, coils, ETB, VCT and the oil pressure control valve. We have changed the harness design compared to the original layout, the Y-split is now located between the two banks at the rear of the engine, between cylinder 4 and 8.

The harness is wrapped using a special automotive high strength and high abrasion resistive polyester tape with acrylic based adhesive. This tape is rated for temperatures up to 300°F.

Installation of level 2 and level 3 kits:

Installing our control pack is straight forward:

- Fit the adapter for the Bosch pressure and temperature sensor on the intake manifold.

- Fit our new engine harness, it comes complete with original connectors, nothing to modify on the engine.

- Plug the throttle pedal in.

- Plug the included power supply harness into the engine harness power connector.

- Connect the two power supply wires according to the instructions.

- Connect the fuel lines and adjust your fuel pressure to 58 psi. Use premium gasoline only.

- Connect the headers to the exhaust system.

Your engine is now ready to be started, no calibration or adjustments are required.

We have done all the hard calibration work.

What to expect performance wise...

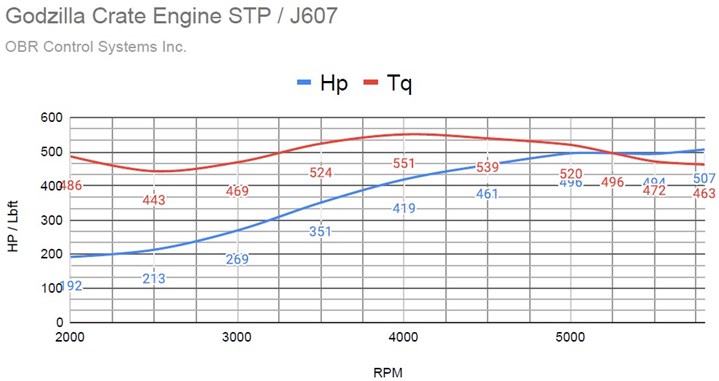

All our calibrations are developed to optimize performance, drive ability and fuel economy. We have spent hours and hours on fine tuning the calibrations we offer for various stages of performance for the Godzilla engine. One thing to bear in mind when looking at power and torque figures is to look at how the engine was tested. Typically the engine is tested without the alternator active and without the exhaust system from the vehicle. We test engines having the original water pump active.

Furthermore, automotive manufacturers claim their performance data according to the J1349 norm while the motorsport industry uses the J607 norm, also called STP for Standard Temperature and Pressure This norm specifies different conditions than the automotive norm and therefor the power rating figures are slightly higher than for performance according to J1349. So, power ratings advertised will therefor be higher than what is originally claimed for the engine.

That said, with our calibration for the standard crate engine we found, in accordance with STP:

Maximum power: 500 hp @ 5,800 RPM

Maximum torque: 550 lbft @ 4,000 RPM

Read more about the Euro-8 ECU features here.

OBD II data export:

Systems and engine harnesses supplied after October 1st 2022 now have a dedicated 16-way standard OBD II connector. You can plug an OBD II scan tool or an OBD II compliant display module into the connector on our wiring harness to read engine data.

Please note that the engine oil pressure is NOT included in an OBD II data export. You can use our separate oil pressure sensor kit to add oil pressure to your OBD II compliant display.

OBD II data channels exported from the ECU include these channels:

- Engine RPM

- Manifold air pressure (MAP)

- Mass air flow (MAF)

- Barometric air pressure

- Fuel pressure

- Fuel rail pressure relative to MAP

- Fuel gauge pressure for DI

- Car speed

- Inlet air temperature

- Coolant temperature

- Engine oil temperature

- Throttle position

- Pedal position %

- Lambda value bank 1 (cylinders 1 - 4)

- Lambda value bank 2 (cylinders 5 - 8)

- Fuel correction on bank 1

- Fuel correction on bank 2

- ECU battery voltage

- Ethanol %

- Turbo RPM

- Exhaust temperature bank 1

- Exhaust temperature bank 2

- Transmission actual gear

Data export via CAN:

In addition to the OBD II data export, the ECU also exports 80 data channels via CAN. With this feature data can be displayed on a CAN based display, exported to a transmission controller or to a data logger.

You can download a document with the specifications from our Support section.

The CAN export is in Big Endian format and the baud rate is 1 Mbit/s.

On-board data recording:

Using the optional communication kit you have access to the ECU's on-board data recording. The logging capacity is 64 Mb and it can record data from 60+ channels.

The ECU software comes complete with a data analysis software.

Vehicle speed and traction control:

The wiring harness is supplied with an auxiliary input connector. In this connector you will find inputs for up to 4 wheel speed sensors. Car speed can be generated from using a single speed sensor triggering off the prop shaft.

If 4 wheel speed sensors are used, one per wheel, a race developed traction control can be activated.

Drag race control and launch control:

A section in the ECU software includes launch control and drag race features. The system will handle a two-step limiter, the transmission lock.

You can control these engine parameters as function of the drag timer. The drag timer starts running the moment you let go of the trans lock switch:

- Target boost pressure

- Actual throttle position

- Spark advance offset

- Engine RPM limiter

- Nitrous control

Gear shift control for manual transmissions:

The software includes a gear shift strategy for use with manual race type transmissions. The strategy includes individual shift settings for each gear for both up and down shift.

Automatic transmission controller:

A stand alone controller is required if an automatic transmission is used. The engine wiring harness has a connector for such a controller, providing connections to:

- Power and ground

- Engine RPM and load

- CAN data export (used by some manufacturers for engine data)

Connection to instrument cluster:

Our ECU can send data via CAN to almost any instrument cluster which have a CAN link for importing data.

We are building a database for instrument clusters for which we have confirmed they will function with our ECU. Please contact us if you are in doubt whether your cluster is able to import data via CAN and how to set it up.

Where to purchase our Godzilla control pack:

Our kit is supplied through selected specialist dealers across the country, these tuning shops can access E8G's software features.

So if you are thinking about modifying your engine, for example by fitting a high performance camshaft, fitting a supercharger or going for a turbo solution, our kit is easily updated to accept such changes. Ask us about these performance updates.

Dealer inquiries are welcome.

OBR development work:

We keep on developing kits and improving current kits.

Lately, we calibrated a 7.3 engine fitted with Brian Wolfe's stage 1 camshaft and an INNOV8 intake manifold with 8 individual runners for each cylinder. Power reached 610+ hp....

Godzilla with Ford Performance intake and 92 mm drive-by-wire throttle body - updated March 2024

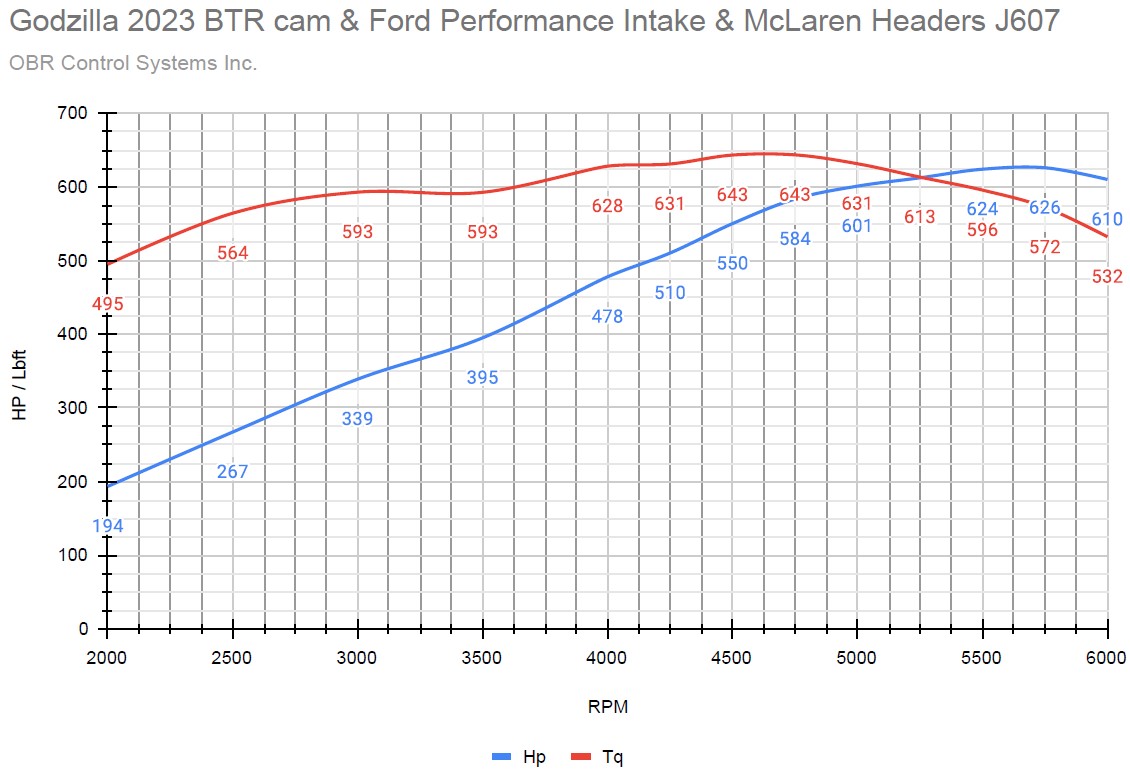

We finished mapping our 2023 Godzilla engine fitted with the new camshaft from Willis Performance / BTR, the Ford Performance intake manifold with a 92 mm throttle body. We ran 2 different tests, one using the standard cast iron headers and the second using long tube dyno headers manufactured by McLaren Performance Technology.

Power speaks for itself - 626 hp @ 5,750 RPM and 644 lb.ft @4,600 RPM.

Look at the available torque, it is above 590 lb.ft from 2,600 to 5,800 RPM:

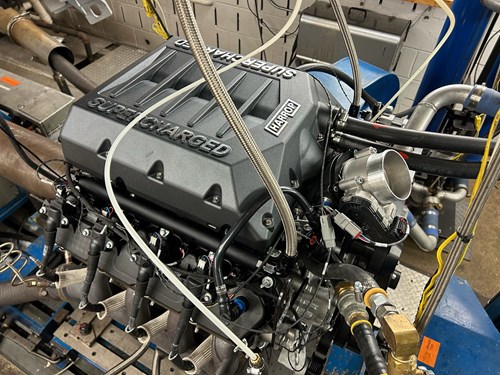

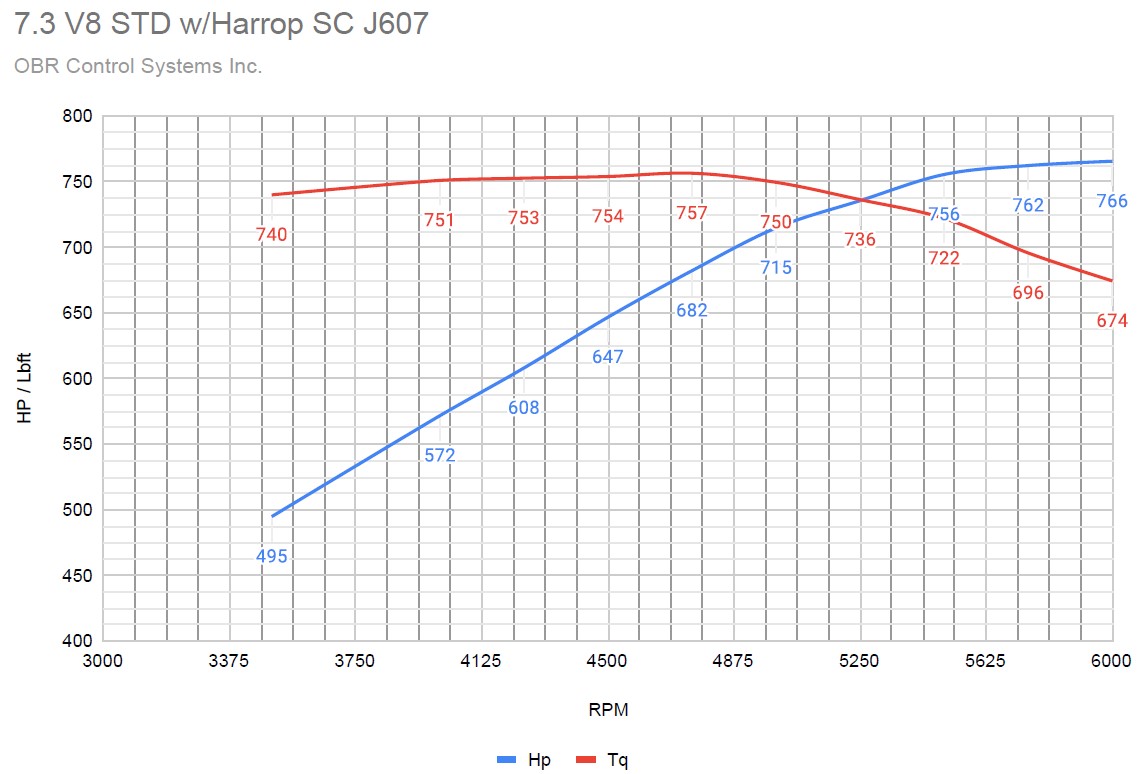

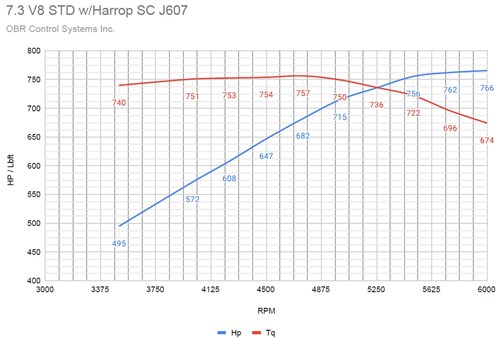

Godzilla with a Harrop Supercharger

We tested an almost standard engine fitted with a Harrop supercharger and our kit #4. The engine was fitted with forged Mahle pistons, our spark plug cables and NGK spark plugs, otherwise standard.

We also used new, beautifully made fuel rails supplied by Indy Power Products.

The performance is outstanding! With 7 psi of boost, the engine developed 766 hp and 757 lb.ft - with 700 lb.ft+ from 2,500 RPM, according to STP norm.

The performance, we achieved is astonishing.

At 2,500 RPM the engine has 700 lb.ft. and at 6,000 RPM the maximum power reached is 766 hp.

Look at an impressive power curve for this engine:

Options for the Godzilla control pack....

Kit options include:

- Coolant plug kit.

- Ford drive-by-wire throttle pedal with wiring.

- Optional closed loop fuel control by adding 2 x wide band lambda sensors to the kit.

- Alternator fitting kit.

- Power supply harness with relays for power, fuel pump and coolant fan.

- Shift controller for 6R80 automatic transmission.

- Fuel pressure sensor.

- Upgrade kit with injectors, new TMAP sensor plus upgraded calibration for boosted engines.

- Traction control.

Coolant Plug Kit

Our coolant plug kit is required to block off the coolant outlet in the block on the driver side by the flywheel.

If you do not require a heater in your vehicle you can use a second coolant plug to block off one of the coolant pipes for the heater. This pipe is located in the front of the block, next to the thermostat housing.

Ford Drive-By-Wire Pedal Kit

This kit is a direct plug in for use with our control pack. Supplied with connection cable.

Wide Band Lambda Sensors

By adding one or (preferably) two wide band lambda (O2) sensors to your control pack the system monitors, regulates and learns the optimum fuel injection.

This is perfect way to ensure your engine always runs at its optimum calibration.

High Flow Fuel Injectors & 3 bar MAP sensor

If you are planning to build a high performance engine with power exceeding 570 hp you will have to consider replacing the standard fuel injectors. These new injectors flow a lot more fuel, rated at 67 lb/hr @ 58 psi fuel pressure. They are a direct replacement of the standard injectors, same length and same connector. These injectors flow enough gasoline to reach up to 1,000 hp with the right fuel pressure. Using E85, there should be enough flow to reach over 700 hp.

The injectors can be supplied as a kit with a manifold air pressure and air temperature sensor, having a 3 bar absolute pressure range. This sensor directly replaces the 1 bar absolute air pressure sensor supplied with our standard control pack. No modifications to the control pack engine wiring harness is required.

This upgrade kit also includes a modified calibration for use with these injectors and the 3 bar MAP sensor.

Fuel Pressure Sensor Kit

150 psi stainless steel fuel pressure sensor kit complete with adapter cable plugs straight into the OBR engine harness. No re-calibration is required, the control pack is configured for use with this sensor kit.

The sensor has a 1/8-27 NPT male thread, compatible with most pressure regulator blocks.

Oil Pressure Sensor Kit for use with OBD II display module

The engine oil pressure information is NOT included in the OBD II data from the ECU. This kit is supplied with a 150 psi stainless steel oil pressure sensor, an adapter between the engine and the OEM oil pressure sensor plus a connection cable. With this kit connected to an OBD II module you can keep an eye on oil pressure.

Specifications: 0.5 Volts = 0 psi

4.5 Volts = 150 psi

Manifold Air Pressure (MAP) Sensor for Supercharged and Turbo Engines

45 psi absolute air pressure and temperature sensor plugs straight into the OBR engine harness. To use this sensor a re-calibration of the control pack is required, please contact us for assistance.

NGK Racing Spark Plugs

We now offer NGK Racing spark plugs for modified engines.

Two versions are currently available, one with heat range 8 and one with heat range 9.

The standard plug is heat range 7.

These spark plugs fits the standard cylinder heads.

High Performance Plug Wires

OBR offers high performance and high quality plug wires. They are made with thick black silicone cable covered fiberglass sleeve, heat resistant to in excess of 1,000 deg F. Coil and plug boots are made with ultra high temperature 45 degree boots with high temperature silicone tape on the spark plug boot. Tabs are stainless steel with a very positive feeling when connected.

Highly recommended on a high performance engine.

Plug Wire Heat Insulation Socks

The heat insulation heat protection socks have an impressive double-layered fiberglass design that will add extra protection to exposed spark plug boots and wires. These socks will protect spark plug boots and wires from header and exhaust manifold high temperatures. The plug wire socks also provide an easily visible way to detect potential burn areas before they occur. They are soft and very flexible, easy to handle and install and will adapt to stretch easily over irregular surfaces.

Performance Upgrade Kit - OB360-23

Godzilla 2023 intake manifold and 86 mm drive-by-wire throttle kit for the 2020-2022 engine versions. Typical gain is +10 lb.ft and +10 hp, measured on standard engine.

CAN2 - to - OBD II Adapter

This adapter is for use with our Godzilla engine harnesses produced before October 2022.

This plugs into the CAN2 connector and provides a link for an OBD II scan tool or a compatible display.

Alternator Fitting Kit

The crate engine is supplied without an alternator. We have a kit available to fit an alternator to the engine.

This kit includes all necessary parts for the installation including the drive belt:

- Alternator

- Bracket

- Belt tensioner

- Pulley

- Mounting bolts

- Belt

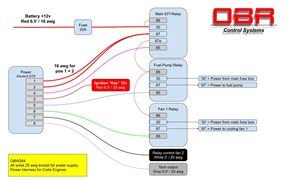

Power Supply Harness

Our power harness for the control pack includes relays for power, fuel pump and coolant fan plus a connection to a tach.

All relays are supplied with a 30A built-in fuse.

This harness is included with control pack kits level 2, 3 and 4.

Automatic Transmission Shift Controller

If you are using a manual transmission, our control pack will work perfectly with your engine and transmission.

To control an automatic transmission a separate stand alone shift controller is required.

There are several options on the market and we shall be happy to direct you to manufacturers, we are working with. Any of these controllers connects directly to our engine harness and secures a trouble-free installation.

Wide Band Lambda Sensor Kit for Engine Development

For engine development work, where the combustion in each individual cylinder must be monitored, please see our kit OB401. The ECU in our control pack can import lambda data from additional sensors via CAN, up to 8 sensors can be added to the system, one for each cylinder.

The 2 main lambda sensors used for fuel control and self mapping connects directly to the ECU.

Control pack for supercharged engine....

The control pack for use with a supercharged 7.3 V8 'Godzilla' engine is based on our E8G ECU, programmed with a tune specifically for this kind of engine performance. As with the standard control pack, this ECU is specially configured to control standard features on the crate engine, you do NOT have to change or modify any sensor or actuator on the engine.

Our 'Supercharger" kit includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

- Power supply cable with main relay and fuse plus connections for fuel pump relay, fan relay and tach.

- E8G gasoline calibration for the standard crate engine fitted with a supercharger, high flow fuel injectors, ignition coils, throttle body and all sensors. Loads of power and torque.

- A performance TMAP sensor is used for this calibration, allowing a boost pressure up to 8 to 10 psi.

- 8 high flow fuel injectors to replace the original injectors on the crate engine.

This kit controls all standard sensors, coils and actuators:

- The standard drive-by-wire throttle body, reading its data stream directly.

- Variable camshaft timing in closed loop.

- Variable oil pressure in closed loop.

- Standard ignition coils.

Installation:

Installing our control pack is straight forward:

- Fit the adapter with the manifold air pressure and temperature sensor.

- Replace the standard fuel injectors with those supplied in the kit.

- Fit our new engine harness, it comes complete with original connectors, nothing to modify on the engine.

- Plug the throttle pedal in.

- Plug the included power supply harness into the engine harness power connector.

- Connect the two power supply wires according to the instructions.

- Connect the fuel lines and adjust your fuel pressure to 58 psi. Use premium gasoline only.

- Connect the headers to the exhaust system.

Your engine is now ready to be started. As this is a non-standard engine installation, it is strongly recommended you check and eventually adjust the calibration settings to suit your installation.

Connection to instrument cluster:

Our ECU sends data via CAN to almost any instrument cluster which have a CAN link for importing data.

We are building a database for instrument clusters for which we have confirmed they will function with our ECU. Please contact us if you are in doubt whether your cluster is able to import data via CAN and how to set it up.

*BREAKING NEWS* - *BREAKING NEWS* - *BREAKING NEWS*

Systems and engine harnesses supplied after October 1st 2022 now have a dedicated 16-way standard OBD II connector. You can plug an OBD II scan tool or an OBD II compliant display module into the connector on our wiring harness to read engine data.

Among ECU data exported are these channels:

- Engine RPM

- Manifold air pressure (MAP)

- Mass air flow (MAF)

- Barometric air pressure

- Fuel pressure

- Fuel rail pressure relative to MAP

- Fuel gauge pressure for DI

- Car speed

- Inlet air temperature

- Coolant temperature

- Engine oil temperature

- Throttle position

- Pedal position %

- Lambda value bank 1 (cylinders 1 - 4)

- Lambda value bank 2 (cylinders 5 - 8)

- Fuel correction on bank 1

- Fuel correction on bank 2

- ECU battery voltage

- Ethanol %

- Turbo RPM

- Exhaust temperature bank 1

- Exhaust temperature bank 2

- Transmission actual gear

Additional, the ECU exports 64 data channels via a separate CAN port. With this feature data can be displayed on a CAN based display, exported to a transmission controller or to a data logger.

Where to purchase our Godzilla control pack:

Our kit is supplied through selected specialist dealers across the country, these tuning shops can access E8G's software features.

So if you are thinking about modifying your engine, for example by fitting a high performance camshaft, fitting a supercharger or going for a turbo solution, our kit is easily updated to accept such changes. Ask us about these performance updates.

Dealer inquiries are welcome.

Emissions

These parts are legal for sale and use on uncontrolled (Non-Emissions Controlled) vehicles and on off-road racing vehicles ONLY.

WARNING: It is against the law to install these parts on an emissions controlled vehicle

All OBR products are exclusively manufactured for racing purposes. Installing these products on any vehicle eliminates the legal use, in any capacity, on public roads/highways and may be subject to fines and/or criminal liability as per the Clean Air Act.

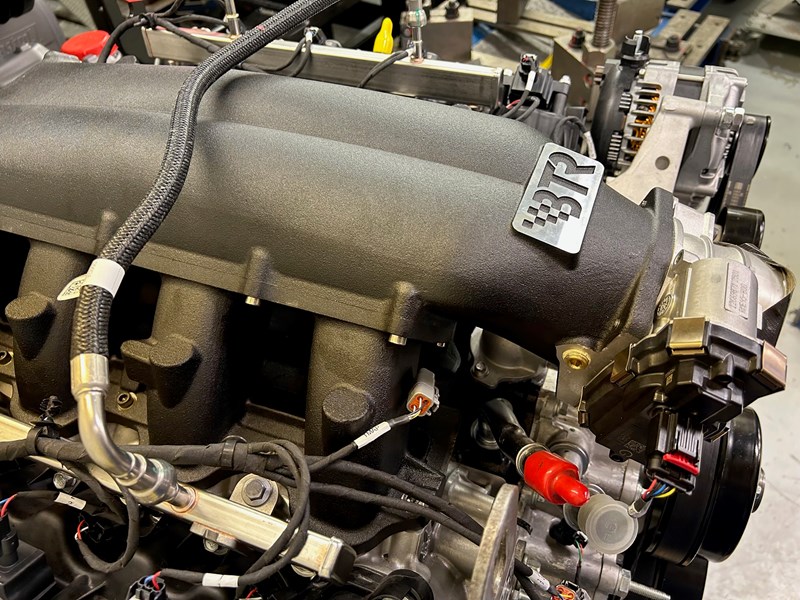

Godzilla engine on OBR dyno, fitted with BTR intake.

Thank you to Billet Pro Shop and Mat Brunette for this presentation of the Godzilla level 2 kit we sent them.

Presentation of our Godzilla engine harness....

Watch what can be achieved by adding a Pro Charger to a Godzilla engine controlled by the OBR control pack.....

965 hp at only8 psi of boost - very impressive. Well done, Brian.

Godzilla performance camshaft installation and power run. Thanks to Revan Evan and Brian Wolfe from Willis Performance Enterprises.

A very interesting oil system for the 7.3 engine from Indy Power Products. Thank you Jim Ryder from IPP, Brian Wolfe and Revan Evan.