OBR Control Packs for Ford Engines - 7.3 V8 Godzilla - 5.2 V8 GT500 - 2.3L 4-Cyl TiVCT GTDi - 7.3 V8 Godzilla 2023 - Coyote 5.0/5.2 - Updated 05.07.2025

Easy Installation - Optimized Driveability - Turn Key Control Pack

Variations

| P/N# | Model | Description | Price in USD | |

|---|---|---|---|---|

| OB220 | Kit | Control pack includes ECU with tune for crate engine, new engine harness, ECU power harness with 3 relays and prepared for use with 2 optional NTK wide band lambda sensors. | 3550 | |

| OB251-F | Pedal | Throttle pedal kit with cable | 169 | |

| OB6312-V | Lambda | Wide band lambda sensor for closed loop fuel control, each | 256 | |

| OB255 | Fuel Press Kit | Fuel pressure sensor 150 psi, supplied with 5' cable for AUX input | 165 | |

| OBW281 | Connector | Connector plug for CAN2 with 1' flying leads and tach pull-up resistor. | 36 | |

| OB256 | Comms | ECU communication & tune kit with connection cables | 397 |

OBR Ford 5.2 V8 GT500 Predator Engine Control Pack - 882 hp.

What the base kit includes....

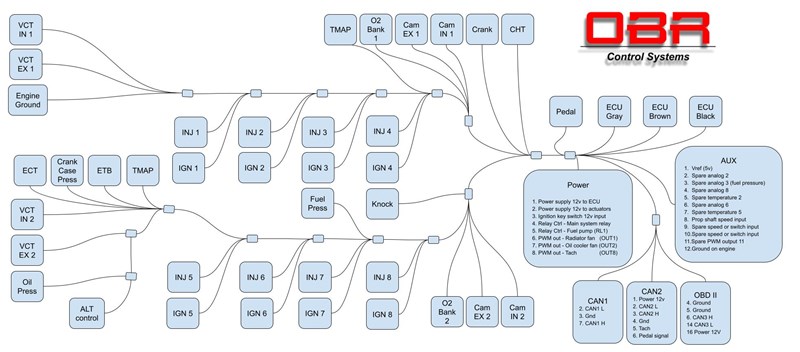

Our kit for the 7.3 V8 'Godzilla' engine is based on our E8G ECU. This controller is specially configured to control standard features on the Ford engine, you do NOT have to change or modify any sensor or actuator on the engine.

All our wiring harnesses are designed and built in our shop in Livonia in Michigan.

Our ECUs are all manufactured in the European Union.

The engine kit OB210 includes these parts:

- OBR E8G stand alone engine controller - ONE single module to control your engine!

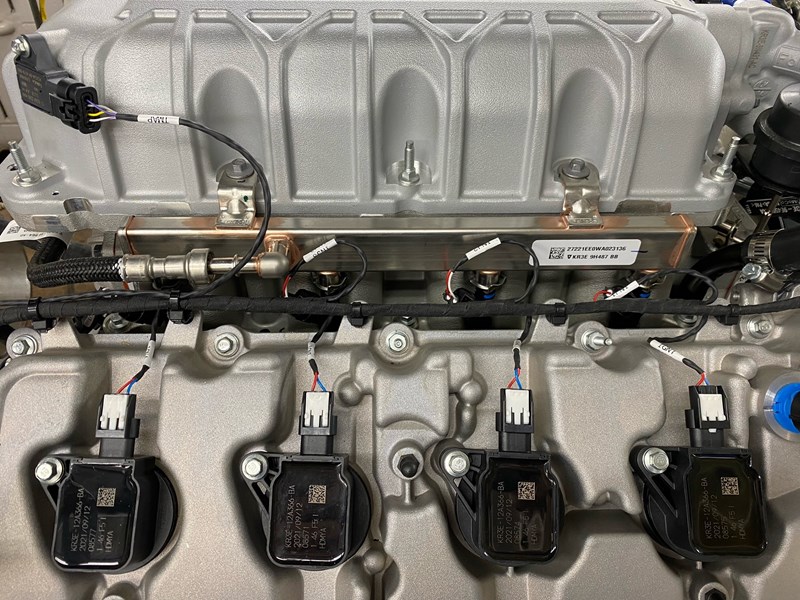

- New OBR high quality engine wiring harness for our E8G controller and with standard Ford connectors for sensors, actuators, coils and injectors.

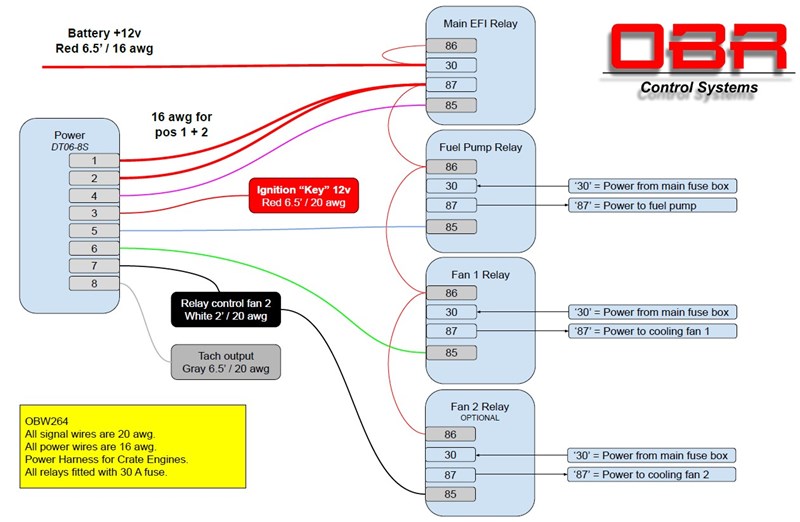

- Power supply cable complete with relays for main power, fuel pump and coolant fan, all fitted with 30A fuses. Furthermore, you will also have wires for your tach and an oil coolant fan.

- ECU programming kit, full access to all software features in the ECU.

- E8G gasoline calibration for the standard crate engine using standard fuel injectors, ignition coils, throttle body and sensors. Loads of power and torque.

- OBD II link.

- CAN data export and import.

---

The kit controls standard components:

- Standard drive-by-wire throttle body, reading the SENT data stream directly.

- Variable camshaft timing for all 4 camshafts in closed loop.

- Standard ignition coils.

- Alternator charging.

To ensure perfect performance the Predator kit can be complemented by adding two NTK wide band lambda sensors. With these connected, the fuel injection works in closed loop mode and will perform self mapping of the injection.

For additional engine development, we can supply a kit with additional 8 lambda sensors, one for each cylinder.

More about our engine and power wiring harnesses

Our harnesses are built here in Livonia and uses aircraft type wire with an insulation of cross-linked, modified ethylene tetrafluoreothylene co-polymer (ETFE). The insulation resists high PH cleaning fluids, fuels, lubricating oils, and many other chemicals.

The wires can withstand extreme test temperatures, ranging from cold bend at -85°F through to 390°F. These wires are a mechanically tough, flame retardant and weight saving solution to many motorsport and aerospace applications.

The engine harness is fitted with new OEM connectors and terminals for sensors, injectors, coils, ETB and the four VCT control valves. We have changed the harness design compared to the original layout, the Y-split is now located between the two banks at the rear of the engine, between cylinder 4 and 8.

The harness is wrapped using a special automotive high strength and high abrasion resistive polyester tape with acrylic based adhesive. This tape is rated for temperatures up to 300°F.

Installation of an OBR control package kit:

Installing our control pack is straight forward:

- Fit our new engine harness, it comes complete with original connectors, nothing to modify on the engine.

- Plug the throttle pedal in.

- Plug the included power supply harness into the engine harness power connector.

- Connect the two power supply wires according to the instructions.

- Connect the fuel lines and adjust your fuel pressure to 73 psi. Use premium 93 octane gasoline only.

- Connect the headers to the exhaust system.

- If you purchased the optional two NTK wide band lambda sensors then fit them in the standard headers.

Your engine is now ready to be started, no calibration or adjustments are required.

We have done all the hard calibration work.

What to expect performance wise...

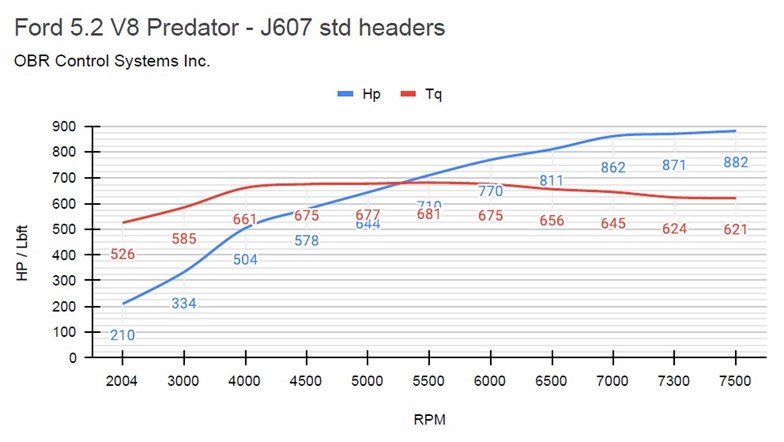

All our calibrations are developed to optimize performance, drive ability and fuel economy. We have spent hours and hours on fine tuning the calibration we offer for the Predator engine. One thing to bear in mind when looking at power and torque figures is to look at how the engine was tested. Typically, engines are often tested without the alternator active, without driving the water pump and without the exhaust system from the vehicle. We have a different approach to engine testing. We create our calibration having the original water pump active, the alternator is active and we use the original air intake and filter.

Furthermore, automotive manufacturers claim their performance data according to the J1349 norm while the motorsport industry uses the J607 norm, also called STP for Standard Temperature and Pressure This norm specifies different conditions than the automotive norm and therefor the power rating figures are slightly higher than for performance according to J1349. So, power ratings advertised will therefor be higher than what is originally claimed for the engine.

That said, with our calibration for the standard Predator crate engine we found, in accordance with STP:

Maximum power: 882 hp @ 7,500 RPM

Maximum torque: 675 lbft @ 4,500 to 6,000 RPM

Read more about the Euro-8 ECU features here.

OBD II data export:

Systems and engine harnesses have a dedicated 16-way standard OBD II connector. You can plug an OBD II scan tool or an OBD II compliant display module into the connector on our wiring harness to read engine data.

Please note that the engine oil pressure is NOT included in an OBD II data export. You can use our separate oil pressure sensor kit to add oil pressure to your OBD II compliant display.

OBD II data channels exported from the ECU include these channels:

- Engine RPM

- Manifold air pressure (MAP)

- Mass air flow (MAF)

- Barometric air pressure

- Fuel pressure

- Fuel rail pressure relative to MAP

- Fuel gauge pressure for DI

- Car speed

- Inlet air temperature

- Coolant temperature

- Engine oil temperature

- Throttle position

- Pedal position %

- Lambda value bank 1 (cylinders 1 - 4)

- Lambda value bank 2 (cylinders 5 - 8)

- Fuel correction on bank 1

- Fuel correction on bank 2

- ECU battery voltage

- Ethanol %

- Turbo RPM

- Exhaust temperature bank 1

- Exhaust temperature bank 2

- Transmission actual gear

Data export via CAN:

In addition to the OBD II data export, the ECU also exports 80 data channels via CAN. With this feature data can be displayed on a CAN based display, exported to a transmission controller or to a data logger.

You can download a document with the specifications from our Support section.

The CAN export is in Open CAN 2.0, Big Endian format and selectable 500 kbits/s or 1 Mbit/s baud rates.

On-board data recording:

Using the optional communication kit you have access to the ECU's on-board data recording. The logging capacity is 64 Mb and it can record data from 60+ channels.

The ECU software comes complete with a data analysis software.

Vehicle speed and traction control:

The wiring harness is supplied with an auxiliary input connector. In this connector you will find inputs for up to 4 wheel speed sensors. Car speed can be generated from using a single speed sensor triggering off the prop shaft.

If 4 wheel speed sensors are used, one per wheel, a race developed traction control can be activated.

Drag race control and launch control:

A section in the ECU software includes launch control and drag race features. The system will handle a two-step limiter, the transmission lock.

You can control these engine parameters as function of the drag timer. The drag timer starts running the moment you let go of the trans lock switch:

- Target boost pressure

- Actual throttle position

- Spark advance offset

- Engine RPM limiter

- Nitrous control

Gear shift control for manual transmissions:

The software includes a gear shift strategy for use with manual race type transmissions. The strategy includes individual shift settings for each gear for both up and down shift.

Automatic transmission controller:

A stand alone controller is required if an automatic transmission is used. The engine wiring harness has a connector for such a controller, providing connections to:

- Power and ground

- Engine RPM and load

- CAN data export (used by some manufacturers for engine data)

Connection to instrument cluster:

Our ECU can send data via CAN to almost any instrument cluster which have a CAN link for importing data.

We are building a database for instrument clusters for which we have confirmed they will function with our ECU. Please contact us if you are in doubt whether your cluster is able to import data via CAN and how to set it up.

Where to purchase our Predator control pack:

Our kit is supplied through selected specialist dealers across the country, these tuning shops can access E8G's software features.

So if you are thinking about modifying your engine, our base calibration is easily updated to accept changes. Ask us about these performance updates.

Dealer inquiries are welcome.

Beautiful built Ford GT replica with our control pack for its Predator engine.

Thank you Allan Uzwiak for sharing.

Short video of our Predator kit in an amazing AC Cobra.